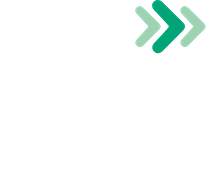

The concept of the circular economy isn’t anything new, but the same approach doesn’t apply to all types of materials. For example, the life of aluminum differs a great deal from the life of plastic as aluminum is infinitely recyclable while plastic is not. Here we explore how a plastic #1 bottle moves through both the linear and circular stages.

What is a plastic #1 bottle?

You may not know it, but all plastics are not the same. And, when it comes to recycling, there are a variety of numbers that classify how something made of plastic can be recycled. Products made of plastic # 1 typically include products like water bottles and peanut butter jars. Since over 60 million plastic water bottles are thrown away each day in the US, we want to go deeper into the lifecycle of creating a plastic bottle.

Sourcing – What is the bottle made of?

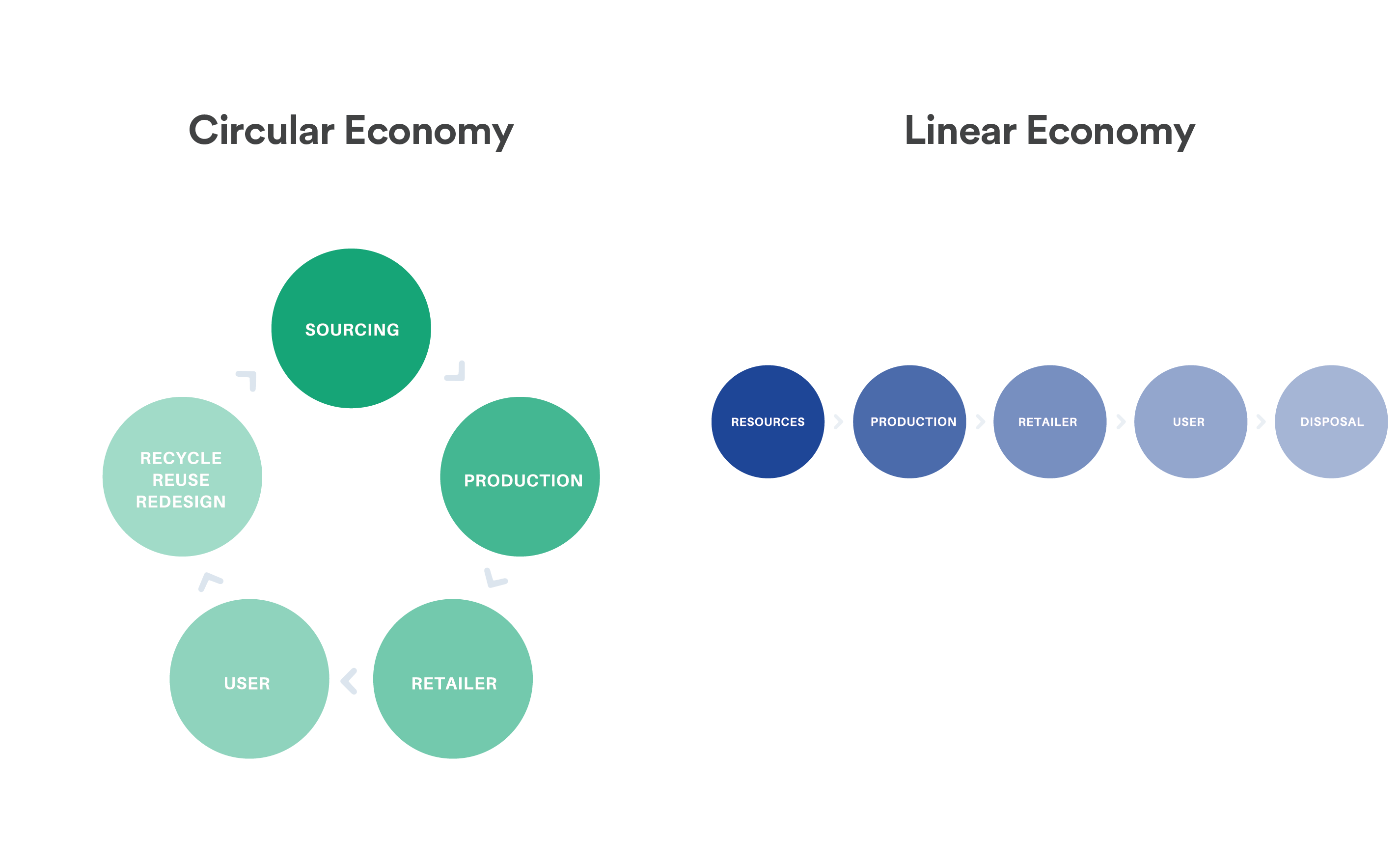

Only 1% of water bottles are imported, therefore, nearly all bottled water sold in the United States are sourced domestically.

Crude oil – used to make polyethylene terephthalate (PET), the main component of a plastic bottle due to it being both strong and light– is removed from the earth through large-scale extraction processes, such as mining, drilling, or fracking. In the United States specifically, crude oil is produced in 32 states and in US coastal waters.

The extracted oil is then shipped to a refinery where the crude oil undergoes its next step, distillation.

Production / Use – How is the bottle made?

The distillation process separates the crude oil into components, called fractions. Each fraction that is separated is a mixture of hydrocarbon chains. The fractions differ in size and structure of molecules and are generally separated into three categories: light, middle, and heavy fractions.

Light fractions result in hydrocarbons: gasoline, naphtha, kerosene, jet fuel, and paraffin. Medium fractions result in diesel fuel and gas oil. Heavy fractions result in fuel oil. PET is produced from naphtha from the light fractions of hydrocarbons. Naphtha is used to produce the base molecules, called monomers, that makeup PET. Two monomers – monoethylene glycol (MEG) and dimethyl terephthalate (DMT) or purified terephthalic acid (PTA), are chemically combined to produce a long, chain-like molecule, the polymer PET, in the form of a pellet. These pellets are melted together using high heat and pressure. Then these resins are injected into a mold of a small tube, called a preform. Once heated back up, air is blown to expand the tube open, similarly to a balloon.

As it cools down, the plastic water bottle is formed. The bottles are filled with water and sealed for use in the bottling process. These bottles are then transported to grocery stores and other suppliers to be bought by consumers.

End of Life – How is a bottle recycled?

Currently 30% of water bottles consumed are never put into a recycling bin despite all the work and energy it takes to make a plastic water bottle.

Recycling

When plastic water bottles and other plastics are collected for recycling, they are taken to a materials recovery facility. All the items are moved onto a disk screen where materials are separated from one another.

Plastics are sorted by categories and by type. Once enough items (not just bottles) made from plastic #1 are collected, they are packed into a large bale and taken to a reclaiming plant where they undergo mechanical recycling. Here, the plastic is shredded into small pieces, sorted, and washed. The small pieces are heated to create small resin to make more plastic material. Mechanical recycling starts and ends with a polymer product – however, the long polymer chains are broken down into smaller pieces, limiting the repeatability of the mechanical recycling process.

In fact, recycled PET is often used to make textiles instead of new bottles. To solve this problem, companies are developing processes to recreate the monomers or hydrocarbons used to make plastic. With PET, organizations are developing depolymerization to regenerate monomers which can replace crude oil and make new plastic material.

What if a bottle isn’t recycled?

When plastic bottles are not recycled, they are sent to landfill where they can take up to 1,000 years to decompose. Moreover, products made from recycled bottles, such as clothing, often end up in landfills as they cannot be recycled with today’s infrastructure.

As we continue to look at our plastic consumption, there are many ways individuals and businesses can reduce dependency. Understanding the impact of how something is made, can benefit how we make purchasing decisions that can have a positive impact on the planet.

Download this blog to share.

We’ll e-mail you a printable version.

To learn more about how to keep waste out of landfill, subscribe to our blog, or speak with one of our TRUE Waste Advisors to learn how to improve waste in your business.