A New York City-based waste and recycling company says it is helping waste haulers streamline operations by providing real-time data, Internet of things (IoT) connectivity and accountability that increases efficiency and insight into waste and recycling service pickups.

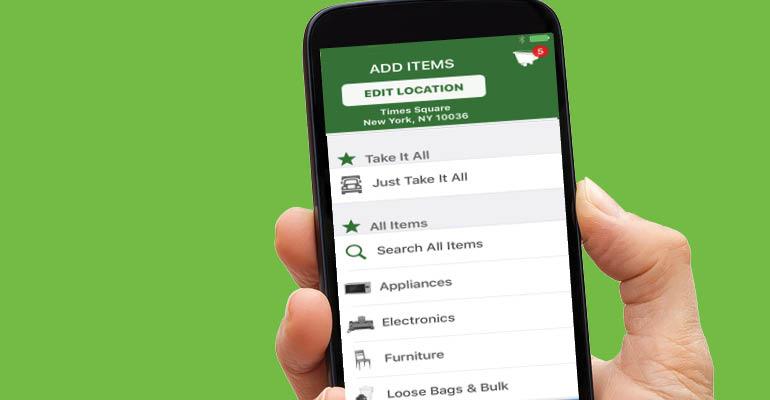

Recycle Track Systems (RTS) provides end-to-end service experience for customers and haulers. It works by sending notifications of waste trucks on location and verifying completion of pickups. It also includes a portal for generators providing access to analysis of new revenue streams, digital LEED reporting and environmental impact data and onsite sustainability training and education for customers. For haulers, onboard tablets help with routing.

“Our technology helps both our customers and haulers streamline the waste flow process. Our customers benefit by knowing when the waste or recycling truck is arriving,” says RTS CEO Gregory Lettieri. “Customers also use our mobile application for ordering additional services such as open top dumpster containers or bulk extras. The added benefit for recycling is we track our recycling loads, including food waste recycling, and validate the tonnage and the facility it is dumped.”

Last month, RTS announced a new partnership with Juice Press, an organic food and beverage retailer with more than 50 locations in New York, New Jersey, Connecticut and Massachusetts.

“Juice Press has long been committed to reducing waste and supporting environmental sustainability,” Shawn Edelman, vice president of food and beverage for Juice Press said in a statement. “By leveraging RTS’s organics diversion and recycling model, Juice Press is taking a pivotal step towards achieving our zero waste initiative, tracking our waste removal and ensuring our food waste is effectively diverted from the landfill and transported to local farms for composting.”

Other sites RTS serves include Whole Foods Market’s New York City locations, construction projects, commercial real estate buildings, restaurants, event spaces and governmental sites.

“Whole Foods Markets was one of our first customers who recognized the additional benefit and transparency,” Lettieri says. “Our hauling partners benefit by leveraging our technology platform, which allows them access to additional nationwide accounts, GPS truck tracking and a platform that allows them to have better routing and pickup efficiency.”

RTS tracks the hauling routes, time, and speed of the vehicles—the trucks and loads to the appropriate recycling facility and then report out on the weights and diversion rate.

RTS built a platform that can assist companies with their sustainability goals, provide reports on a monthly or weekly basis and the tools to divert from the landfill—backed up by metrics and routing technology.

“As RTS continues to expand, we will continue to provide routing efficiency for our haulers, which will reduce truck traffic, time on the route and less emissions,” says Lettieri. “By focusing on recycling tracking, we know exactly what was diverted from the landfill and where our partners and customers can focus their resources to reach their sustainability goals, which all leads to additional material being diverted from the landfill.”

Lettieri says the company thought their biggest challenge would be getting waste haulers to adopt the technology.

“Fortunately, we showed our haulers and customers our value very early on. We thought it would be difficult to have waste haulers sign up for the platform, however we realized when we showed them our value and our access to additional clients,” he says. “We had access to haulers who had the same goals as us. RTS is an asset light waste technology company. We do not own hauling trucks, which means our partnerships with haulers are the key to our success.”

– Megan Greenwalt | Waste360