Construction and demolition waste, or C&D waste, is the term used to describe the debris generated by all kinds of construction and demolition projects. As C&D materials are produced by undertakings ranging between the construction of private homes and the deconstruction of international airports, they represent an enormous source of waste.

In fact, the EPA estimates that the US produced 600 million tons of C&D waste in 2018, which is double the quantity of Municipal Solid Waste (MSW) produced in that same year. Perhaps unsurprisingly, approximately 90 percent of C&D waste is generated from demolition, and 10 percent from construction.

Source: rts.com

In order to mitigate the financial and environmental costs of this quantity of waste, the EPA has established a Sustainable Materials Management (SMM) approach for businesses and organizations which interact with C&D and all other waste streams. This SMM approach helps organizations to identify which C&D materials are best fitted to be reused or recycled and explains how they can do so.

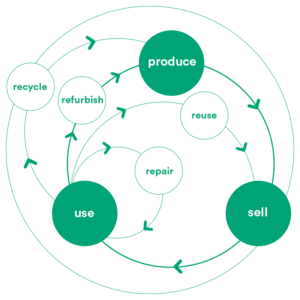

Reusing and recycling C&D materials is important for a number of reasons. In general terms, doing so is an excellent example of the benefits of circular economy in action, as it helps to divert significant levels of waste away from landfill, and in doing so mitigates the need to extract new raw materials from the earth. Both of these elements help to reduce environmental degradation for products at both start-of-life and end-of-life.

Reusing and recycling C&D materials can also reduce financial costs, from the expenses associated with raw material extraction, processing, and transportation to the buying of new goods and their eventual disposal. Moreover, establishing strong C&D reuse and recycling systems can support localities by producing plenty of jobs and by helping to maintain the architectural style of an area through the reintegration of locally sourced materials.

What’s more, the value of a more robust and flexible reuse and recycling program for C&D materials is likely to grow as urbanization in the US continues to accelerate and the need for cycling back useful materials into the economy becomes apparent. Here then, we examine some of the challenges facing the C&D recycling industry and how greater diversion and recycling might be achieved.

What are the Problems with C&D Recycling?

C&D recycling has a wide range of benefits and the EPA reports that of the 600 million tons of C&D waste produced, approximately 455 million tons are effectively recycled and 145 million tons are sent to landfill. Whilst this a significantly larger proportion than many other waste streams, it still demonstrates that a large amount of waste is being sent to landfill.

There are a few reasons for this. Traditional demolition practices make it difficult to reclaim valuable resources, as wholesale destruction of buildings and structures can create a blended rubble mix from which it is difficult to extract reusable materials. Even with more conscientious deconstruction, materials must be carefully organized and properly separated into distinct categories on site; if this process established at the start of a project, then the recycling process quickly becomes near impossible further down the line.

Sometimes, even well separated materials can end up contaminated, such as scraps of wood or plastic entering concrete destined to be used as aggregate. COVID 19 has also been found to have a negative impact on the C&D recycling industry, as some recyclers have had to drastically reduce the number of the staff who work in their sorting facilities.

These difficulties are, in turn, exacerbated by the broad range of materials which make up C&D. Between construction and deconstruction, C&D materials can include concrete, wood, asphalt, gypsum, metals, bricks, glass, bitumen, plastics, tree stumps, pipes, cables, as well as whole doors, windows, and appliances. This list is far from comprehensive but serves to demonstrate just how many materials must be properly separated and handled in order to allow for effective recycling.

Why is Improper C&D Recycling a Problem?

Where recycling C&D has its benefits, failing to do so creates problems to the opposite effect. The extraction, manufacture, and subsequent disposal of concrete and other Portland-cement based products is a case in point, with some figures suggesting that, after water, it is the most widely used substance on the planet.

This overreliance on such a polluting substance, made from raw materials for each new construction project has numerous implications. From a financial point of view, the number of reclaimable materials which may be available close to sites of new construction may help reduce the use of concrete and other materials. This avoids the costs of disposing of those products, and also extracting raw materials to create those products in the first place.

The environmental costs of failing to recycle are drastic as well. The extraction of raw materials often leads to the degradation of soil quality; it can be the cause of deforestation, it can wreak havoc on biodiversity, and it often leads to the displacement of people. This process is explained in greater detail in the Story of Stuff.

Equally, the disposal of materials through incineration and landfill can contribute to the leaching of toxic chemicals into local water supplies, and has been proven to create dangerous environmental conditions which most affect the politically vulnerable, thus contributing to environmental injustice.

How is construction waste recycled?

Fortunately, the proper recycling of C&D is possible with good organization and planning. The EPA SMM plan details plenty of ways in which a range of resources can be effectively reused. For example, established fixtures such as doors, windows and appliances can be easily extracted and removed to a new construction site. Pre-cut wood can be used for lintels and other smaller wooden features, which circumnavigates the need to cut these features from whole pieces of timber.

Bricks and concrete can be reused in a range of forms to serve various functions, from providing aggregate for the construction of new concrete, to acting as the foundation for driveways. Paint can be remixed and reused as a primer coat, and packaging materials can often be returned to the suppliers who delivered them, allowing these materials to be used again. The SMM plan acts as an excellent guide for the best practice on how to reduce, reuse and recycle C&D materials.

Asphalt and concrete can be recycled on-site or at a recycling center using a crushing rig and can be used to support the construction of new roads and pavements. Porcelain can be crushed and resold to tile manufacturers, which can produce tiles made with up to 40% recycled materials. Steel can be melted and reformed without degrading, which means it can be recycled perpetually, and wood can be chipped to make particle boards, pallets, or to create mulch for the protection and improvement of soil. Even carpet and insulation can be reused to produce underlay padding and fiberglass tiles.

There is a vast array of opportunities for us to develop a circular economy using C&D materials, offering environmental, financial and economic benefits. All we need in order to access these is to implement good practices and increase how much demolition waste is typically recycled.

How Can We Increase The Amount of C&D Which is Being Recycled?

There are a number of ways we can increase the proportion of C&D material which is recycled. The first and most important tool is good organization. By communicating well with C&D recycling companies, you can ensure that you have the appropriate containers on site which are ready to accept suitably separated materials from the very beginning of your project.

The recycling of materials is not a difficult process, and by ensuring that recyclable materials are not mixed with one another you will have created conditions in which recycling can most easily take place.

Another change which can have a significant impact is to implement more conscientious building design. Designing buildings which can easily be disassembled facilitates more effective reuse or recycling of whole materials at the end of that building’s life. Equally, this process allows the building to be more easily adapted to serve new purposes.

Finally, it is vital to ensure that you’re working with a reliable recycling company. Even if you follow the exact instructions laid out by your recycling company, you can only guarantee that they will recycle those materials correctly if you are sure that they are operating within the proper parameters and regulations set by your state or municipal government.

At RTS, we can offer you all the support you need to be reassured that your C&D material is being recycled in the best way possible. Our business was established to support the development of the circular economy, and both our philosophy and operations are targeted towards making this a reality. Evaluating our waste impact and delivering meaningful solutions are our highest priority, so we’ll adapt ourselves as best we can to meet your needs.

We offer a range of services, including on-demand and regular C&D waste pickups, the provision of dumpsters in a variety of sizes which can be ordered through our app, and which are available across the US. This means that wherever you are, we can help you organize your C&D waste, then find the best next use for it.

We also offer 24/7 customer support and waste diversion reports for full accountability, which means that you can rest assured that your C&D waste is being utilized in the best way possible. It’s incredibly easy to get started. To begin recycling your C&D waste with us, you can apply for a free waste assessment. We’ll work with you to identify exactly what your waste needs are and develop a customized plan to help ensure that your C&D waste gets exactly where it needs to go.