In Action Partnerships in every industry.

Partnerships in every industry.

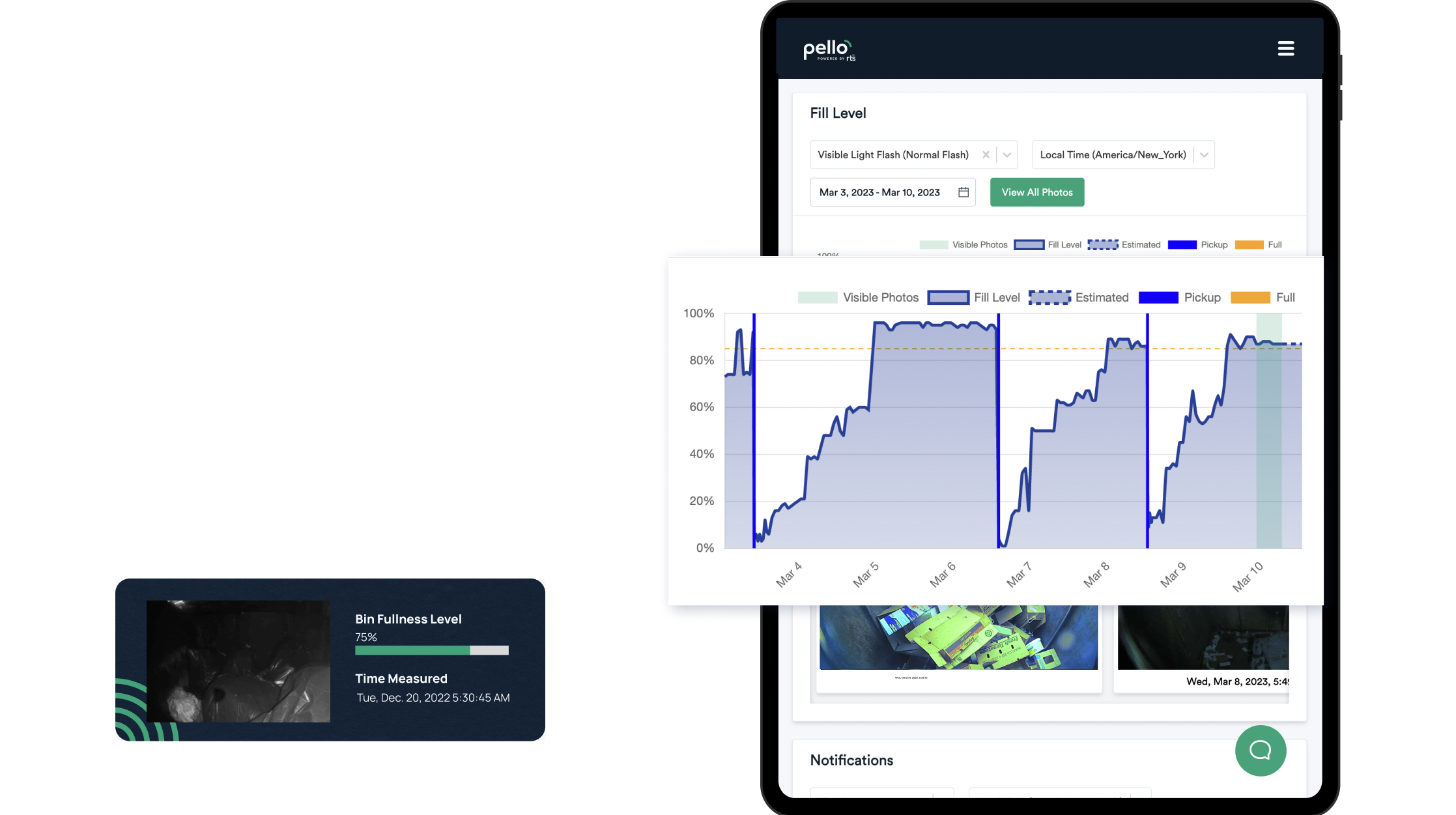

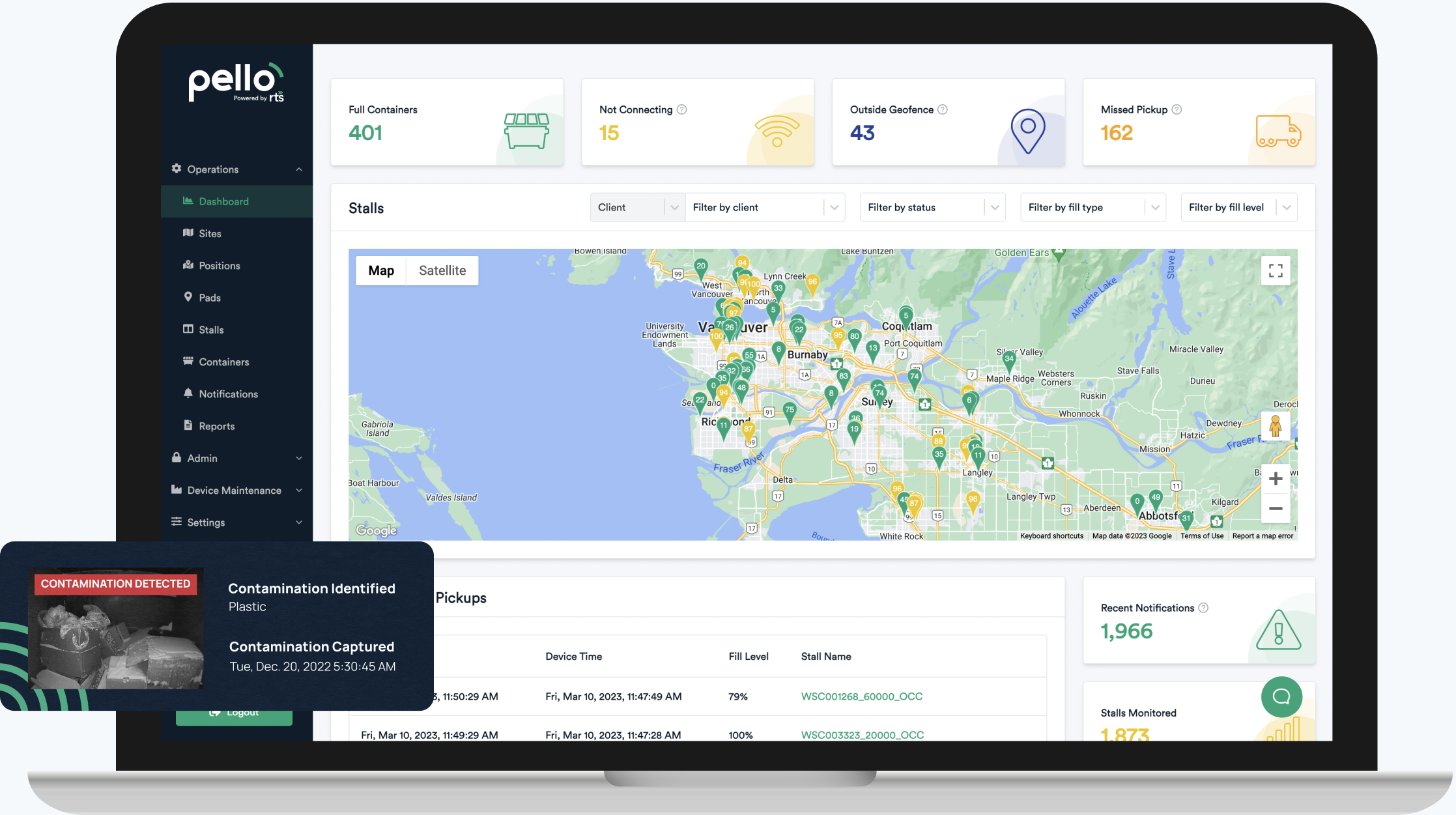

Meet Pello’s Control Center

The Pello Dashboard offers everything at your fingertips, providing an easy snapshot of the key operational metrics you depend on, such as fill level and contents, contamination and pickup alerts, bin location, and temperature. Accurate reporting supports your ESG goals and regulatory requirements.

- Manage hauling and assets

- Automate & right-size pick-ups

- Prove your ESG commitments

Deploy Pello’s Cutting-Edge Sensor

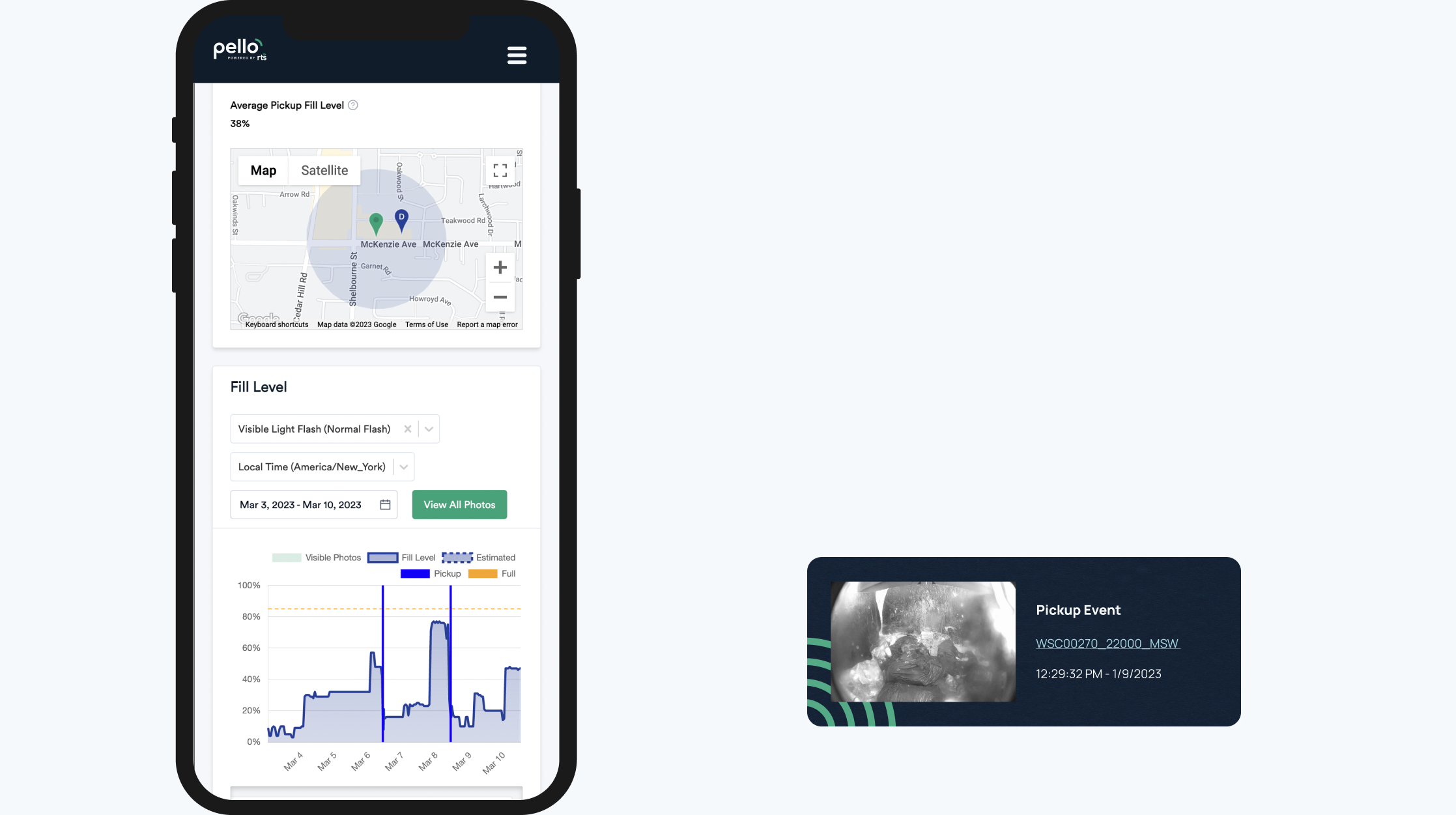

See inside your bins, in real time. Pello’s sensor technology for waste and recycling containers is a leap forward in managing waste effectively. The Sensor tells you what is in your container, where it’s located, its fill level, pickup alerts, and the type of contamination impacting in your bins.

- Monitor bin fill levels

- Track container locations

- View contamination

Reduce Emissions and Increase Diversion

Sustainability is what drives RTS to continuously search for solutions that are good for our clients and the planet. Pello’s technology allows for real-time data to lead decisions – not guesswork. Fewer trucks on the road means money and resources saved, and even cuts down on traffic.

- Reduce C02 emissions

- Detect contamination earlier

- Meet zero waste goals

Scale your Sustainability with RTS

With nearly a decade of experience integrating full-service waste management and zero-waste systems into campuses, conference centers, universities, and municipalities, RTS supports customers across North America.

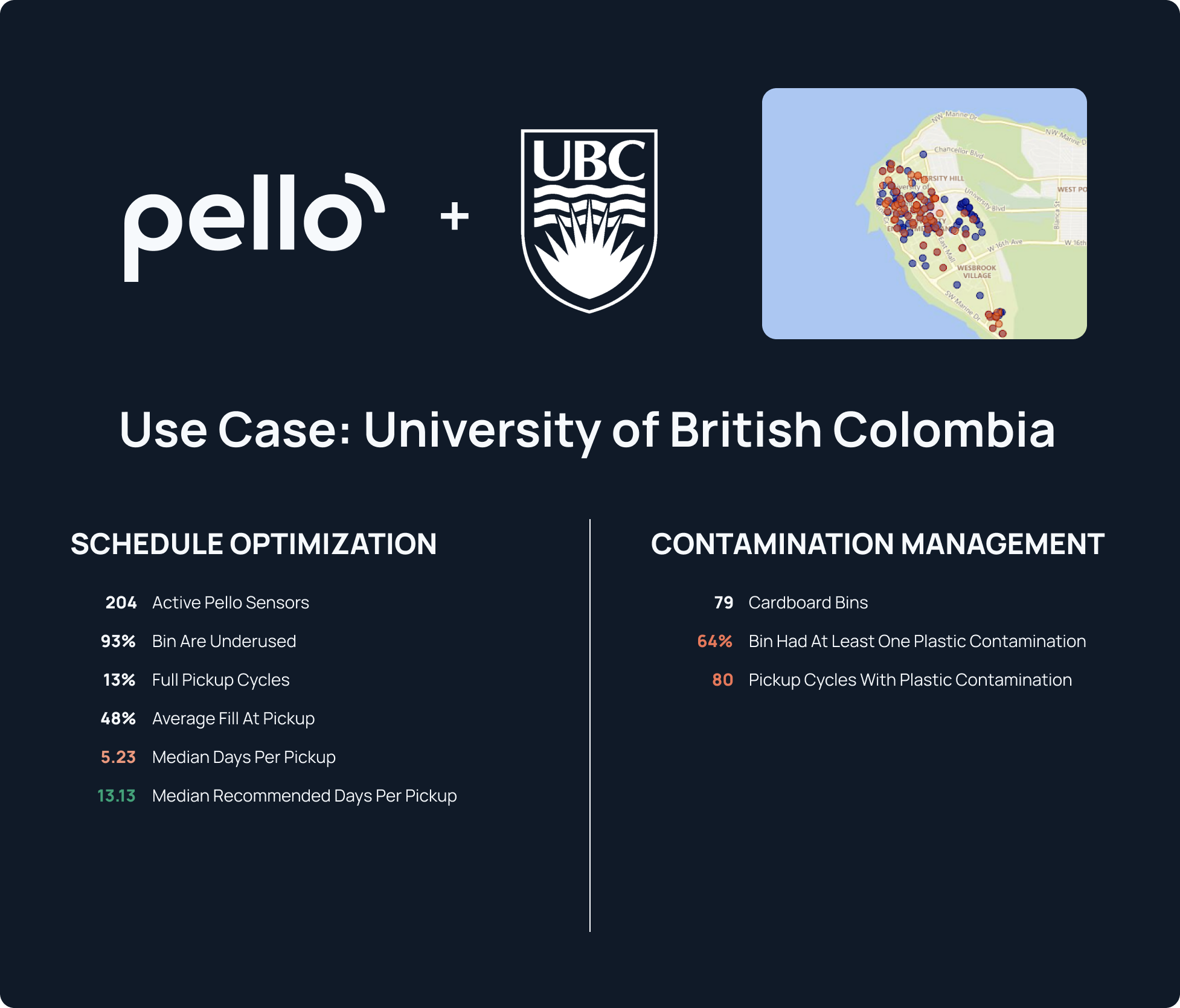

Pello In Action: Use Case

How Pello’s Contamination AI Increased Efficiency

+ Reduced Environmental Impact at one of Canada's Largest Universities

+ Reduced Environmental Impact at one of Canada's Largest Universities

Problem

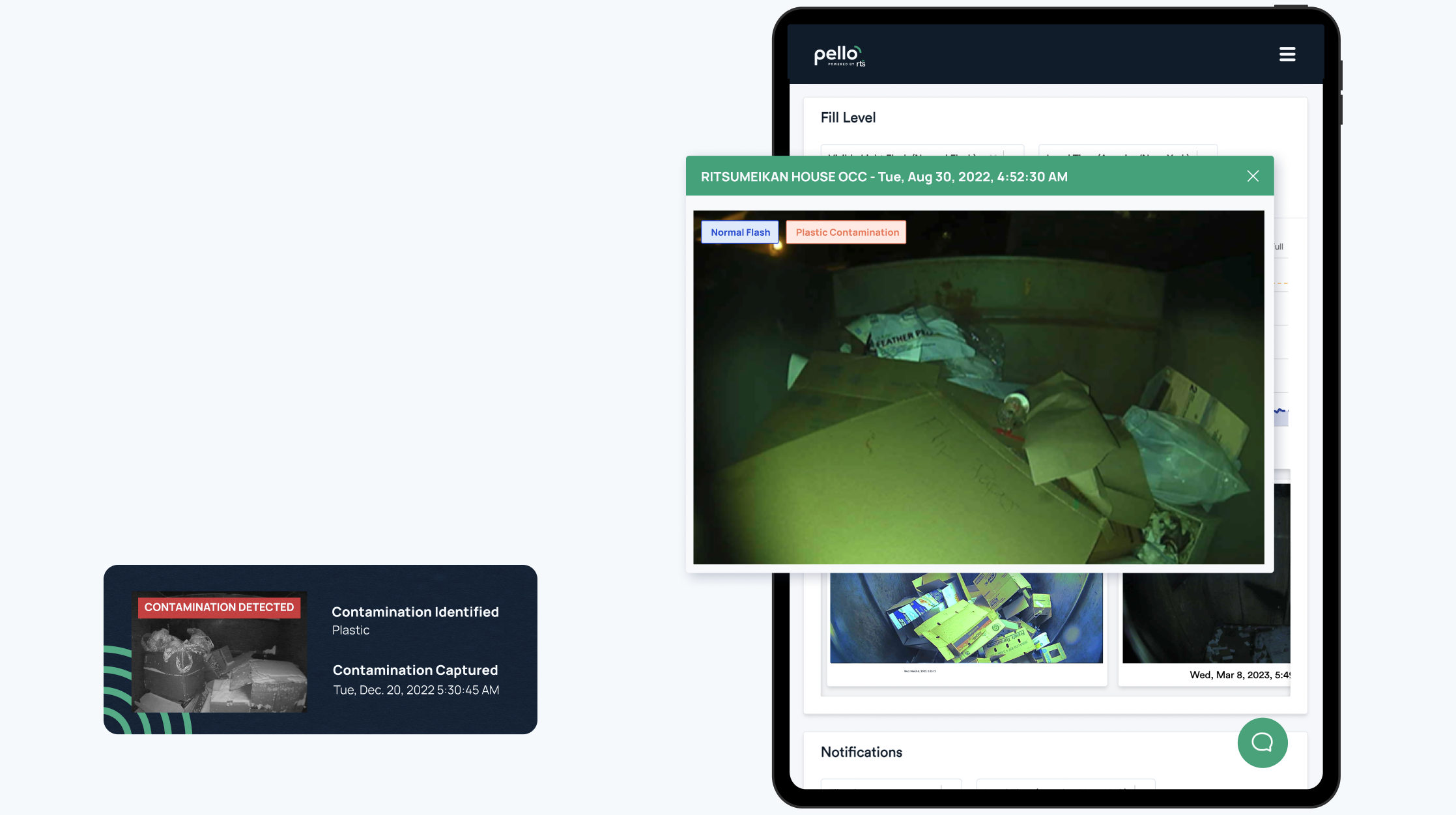

Customers receive surcharges, face compliance issues, and miss diversion goals because of waste contamination.

Hypothesis

It’s possible to increase efficiency and increase diversion rates through contamination identification.

Research

Pello Sensors and live cameras installed to detect bin fullness and contamination. Sensors identified 48% average bin fullness at pickup and cardboard bins as having plastic contamination in at least 64% of bins. Pello deployed an AI-deep learning model to detect plastic bags in cardboard bins.

Findings

Customer’s potential savings increase exponentially: When customer receives live contamination notifications and is able to rectify contamination prior to pickup, in addition to shifting schedule to account for bin fullness can save the customer money.

How it Works

Learn how Pello increases

operational efficiency and sustainability.

operational efficiency and sustainability.

Monitor Bin Fullness

With real-time updates and notifications on your Pello dashboard, you can monitor bin capacity and address waste needs, reduce unnecessary trips and emissions, avoid waste overflow, contamination, and additional costs.

Smarter Pickups

Imaging AI and fullness data identify pickups with over 95% accuracy, enabling operational and scheduling efficiencies, cost savings and on-time payments, and reduction of GHG emissions by eliminating unnecessary hauls.

Spot Contamination

In-Sensor Cameras detect contamination events and alert you immediately, providing detailed reporting to track patterns as well as recommend solutions to reduce contamination.

Real-Time Asset Tracking

Remotely monitor the location of your assets (waste bins), their movements, and protect them from theft, unexpected events and maintenance through real-time Asset Tracking notifications.

Want to improve your waste and recycling operations?

Contact us to learn more or request a demo.